| Describe the nature of the sector of industry and their role and responsibilities as a plant operator |

• Industry type

• Customer / client needs

• Sector contribution

• Role

• Reporting structures

• Lifelong skills

• Working practices |

• Communication with colleagues / management / other trades

• Health and Safety at Work Act

• Environmental issues

• Other trades

• Social responsibilities |

| Name and explain the purpose of principal components, the basic construction, controls and terminology |

• Differing types

• Functions and applications

• Power units

• Hydraulic systems

• ROPS / FOPS

• Chassis / steering / tyres Inc. pressures / ply rating and importance of replacement with same |

• Stability

• Booms

• Forks

• Safety / stability systems

• Counterbalancing

• Attachments and accessories

• Hoist ropes / hook blocks

• Access systems

• Safe load indicator equipment

• Remote control units |

| Conform with manufacturer’s requirements as per the operator’s handbook, other types of information sources and relevant regulations and legislation |

• Operator’s Manual

• Machine decals

• Health and Safety at Work Act

• PUWER/LOLER

• PPE

• Rating plates

• Codes of Practice

• Site plans / drawings

• Duty charts/Load charts

• Familiarisation |

• Method statements

• Lift plans

• Lifting requirements and limitations

• Risk assessments / COSHH

• Inspection and reporting requirements, daily weekly thorough examination, both for equipment and accessories |

| Undertake and record all pre-use checks |

• Regular and non-scheduled maintenance procedures

• Checklists |

• Sequence of pre-use checks

• Defect reporting

• Company polic |

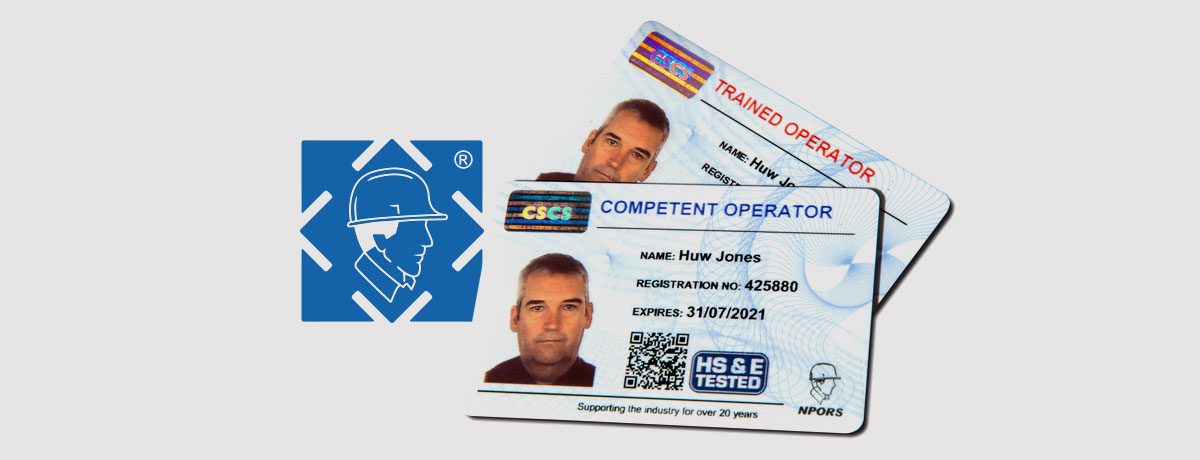

| Explain the need and function of appropriate documentation |

• Certification (CE for machine & attachments)

• Thorough examination (machine and accessories) |

• Relevant site-related documentation

• Pre-use checks/inspections

• Operator’s handbook |

| Configure and ready for travel (site and highway) |

• Driving controls

• Attachments

• Driving position

• Type and security of attachments |

• Visibility

• Road Traffic Act (attachments etc.)

• Site (towing) |

| Travel over level surfaces and on rough, undulating ground and inclines, with and without loads |

• Driving controls

• Ground conditions

• Traction / aids

• Inclines and techniques

• Hazards

• Travel speeds

• Load swing and impact on equipment |

• Working area / routes

• Site and road travel

• Environment protection / minimise damage

• Load protection

• Stability/centres of gravity

• Locking axles |

| Manoeuvre in areas with limited space, with and without loads |

• Visibility

• Limitations of vision

• Steering options

• Proximity hazards |

• Protection of ground / tight turns

• Environmental / noise / fumes

• Travel speeds |

| Arrange and follow given signals and instructions when travelling and manoeuvring with and without loads |

• Code of signals (hand)

• Signaller location

• Visibility

• Signalling methods

• Types of hand signals

• Hand signal compatibility

• Verbal instructions |

• Codes of practice

• Communication types and limitations

• Radio set-up

• Radio protocols

• Visibility

• Multiple signalling |

| Configure and set for all lifting, loading and transferring duties |

• Best method for safe load movement

• Lift plan

• RAMS

• Positioning / planning

• Required configuration

• Lifting controls

• Machine capacity

• De-rating

• Load Moment Indicators

• Load charts

• Attachments |

• Load centres / C of G

• Environmental conditions

• Levelling

• Site markings

• Fork spacing

• Hazards

• Load weights

• Deploy stabilisers

• Rated capacity indicators

• Levelling devices (axles)

• Ground conditions |

| Attach and remove various attachments |

• Attachment types and function

• Preparation procedures

• Attaching and removal procedures

• Storage requirements

• Machine configuration and positioning |

• Manual handling

• Using assistance

• Securing requirements and essential pre-use checks

• Post-fitting checks

• Load charts |

| Attach and remove hoist-rope attachments for the movement of suspended loads |

• Attachment types and function

• Preparation procedures

• Attaching and removal procedures

• Storage requirements

• Machine configuration and positioning |

• Manual handling

• Using assistance

• Securing requirements and essential pre-use checks

• Post-fitting checks

• Load charts |

| Explain actions required for proximity hazards Inc. underground and overhead services |

• Types of typical services

• Warning / identification systems |

• Reporting procedures for damage to services

• Minimum distances and clearance |

| Explain the basic principles of the slinging of loads, types of lifting accessories that can be used and the correct and incorrect methods for attaching suspended loads to the machine |

• Signalling procedures

• Techniques

• Types of loads

• Machine stability

• Effects of incorrect methods of attachments

• Function

• Application

• De-rating |

• Load stability / security

• Environmental conditions

• Load characteristics (loose/bundled/fluid etc.)

• Accessory compatibility

• Slinging angles

• Load weight

• SWL/WLL

• Limitation of slinging duties |

| Explain the requirements for ensuring adequate ground support and stability |

• Tyre pressures

• Ground conditions/assessments

• Lift plans

• Point loadings

• Machine bearing pressures/point loadings

• Ground bearing capacity

• Factors of safety

• Environmental effects Inc. severe weather

• Sole plate material/ composition |

• Spreading of load/sole plates

• Ground improvement

• stabiliser extension/short rigging

• Application of full or some stabiliser use

• Underground services

• Ground structure and composition

• Terrain/topography

• Previous use of ground

• Temporary works |

| Explain the causes of instability during blocked, free-on-wheel and pick-and carry duties |

• Effects of swinging loads

• Dynamic forces

• De-rating of slung loads

• Load size

• Ground conditions |

• Factor of safety

• Travel configuration

• Proximity hazards

• Regulations/guidance

• Environmental conditions |

| Lift and place various suspended and fork-mounted loads from a variety of locations including a vehicle |

• Best method for safe load movement

• Lift plans

• Required authority

• Guidance and regulations

• Load charts

• Environmental conditions

• Machine suitability

• Preparation

• Loading towers / platforms / racking / stacking

• Undercutting |

• Load types

• Attachments/accessories Inc. limitations and design use

• Working area

• Identification of proximity hazards

• RCI/LMI settings

• Types of trailer / transporter

• Transporter capacities

• Procedures / weight distribution

• Materials / vehicle protection |

| Lift and place suspended and fork-mounted loads under blocked, free-on-wheels and pick-and-carry duties |

• Load charts

• Stability

• Trial lifts

• Ground conditions

• Lifting controls

• RCI/LMI information

• Jib extensions |

• Visibility

• Environmental conditions

• Load stability/security

• De-rating requirements

• Following instructions

• Travel routes |

| Lift, transfer and place fixed- hook suspended loads up to maximum extension, at full of working height and using the full slewing capability of the machine |

• Configuration

• Ground conditions / hazards

• Visibility

• Load security / travel position

• Signalling / following instructions |

• Stability

• Loading towers / platforms / racking / stacking

• Protection of structures / loads

• Overhead obstructions

• Lift plans |

| Lift, transfer and place hoist- rope suspended loads up to maximum extension, at full working height and using the full slewing capability of the machine (Blocked duties) |

• Configuration

• Ground conditions / hazards

• Visibility

• Load security / travel position

• Signalling / following instructions

• Stabilisers |

• Stability

• Loading towers / platforms / racking / stacking

• Protection of structures / loads

• Overhead obstructions

• Lift plans |

| Lift, transfer and place fork- mounted loads up to maximum extension, at full working height and using the full slewing capability of the machine (Free-on-wheels) |

• Configuration

• Ground conditions / hazards

• Visibility

• Load security / travel position

• Signalling / following instructions

• Lift plans |

• Stability

• Loading towers / platforms / racking / stacking

• Protection of structures / loads

• Overhead obstructions |

| Minimise the swinging of suspended loads during travel |

• Travel routes

• Accessory types

• Poor/uneven ground

• Slopes/inclines

• Effects of swinging loads

• Hand & tag lines |

• Travel speeds

• Stability

• Observation/anticipation

• Load characteristics |

| Explain how stability is affected by travelling with a raised / extended boom and/or rotated upper structure with suspended loads and fork-mounted loads (both regular and irregular) |

• Centres of gravity

• Swinging of loads

• Environmental factors/extreme weather

• Dynamic forces |

• Ground conditions

• Slopes/inclines

• Travel speeds

• Travel routes |

| Explain visibility issues and restrictions with suspended and fork-mounted loads |

• Load size

• Load swing

• Carrying height of load

• Maintaining vision with slinger/signallers |

• Direction of travel

• Assistance for travelling

• Typical proximity hazards

• Ground conditions |

| Place suspended loads out of sight of the operator |

• Communication/signalling

• Signaller positioning |

• Stability

• Proximity hazards |

| Maintain safe working situations |

• Stability

• Load security |

• Hazards |

| Maintain safe and tidy working areas |

• Specification

• Stacking |

• Load positioning / storage

• Proximity hazards |

| Carry out shut down and securing procedures |

• Shut down procedures

• Security

• Configuration |

• Parking and positioning

• Isolation of remote units

• Reporting of defects |

| Explain the loading and unloading procedures for machine transporting |

• Compatibility

• Positioning

• Ground conditions

• Access / egress / working at height |

• Types of transporter

• Security

• Configuration

• Loading responsibility |